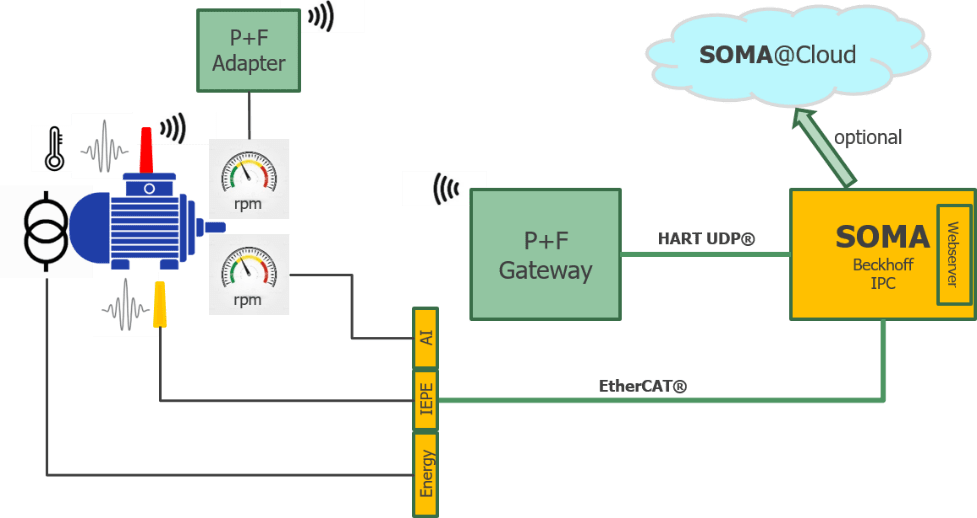

On the basis of our SOMA platform, a modular and scalable edge device was developed as a prototype for monitoring bearing and machine components using wireless sensors for a well-known Japanese bearing manufacturer. Based on the customer requirements, the state of the art was determined and a functional specification created. The hardware was selected on the basis of the specification requirements. The chosen option was a Beckhoff® IPC C6030 (edge device) and a gateway from Pepperl+Fuchs to set up a secure wireless network for connecting wireless sensors, such as vibration sensors.

Use case:

Wireless bearing and machine monitoring with SOMA

Sector:

Industry

Technologies:

SOMA

Project description

The following test setup was used on the customer’s test bench (bearing monitoring) to benchmark wireless and wired sensors:

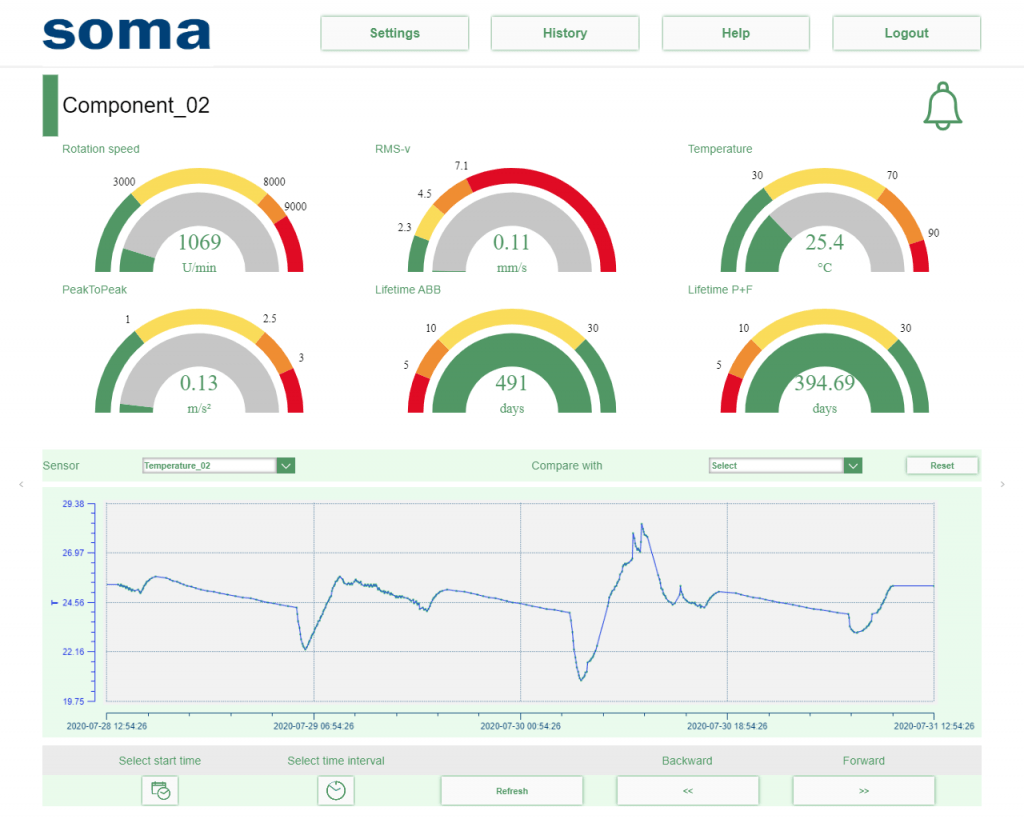

The visualization in SOMA shows a selection of the test data recorded:

The benchmarking of wired and wireless sensors showed no quality differences in the detection of defects in prepared test specimens (different bearings).

Contact us:

Please feel free to reach out to my team and me with your project requirements. We would be happy to give you an initial overview of how our experienced developers can meet your individual goals.